How Metal Spinning Enhances Efficiency in Oil Rig Manufacturing

The Role of Metal Spinning in Oil Rig Manufacturing

Overview of Metal Spinning

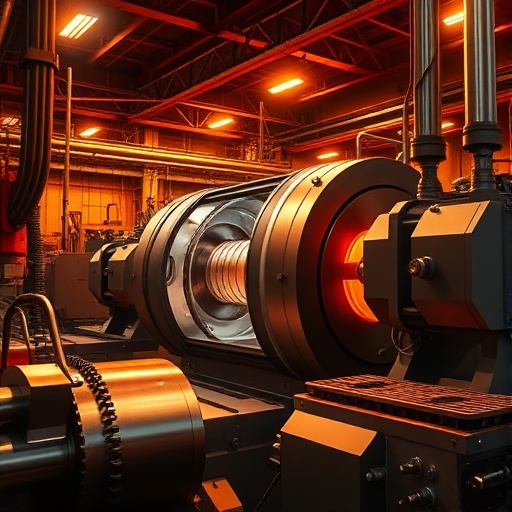

Metal spinning transforms flat metal discs into seamless, rotationally symmetrical shapes like cylinders and cones, essential for oil rig components. Manufacturers press a spinning metal blank against a rotating mandrel using specialized tools, creating strong, uniform parts without welds. In the oil and gas industry, this process shapes pipes, pressure vessels, and structural elements that withstand harsh offshore conditions. Experts in metal working rely on spinning to produce high-precision items that support gas production and oil extraction. Unlike basic stamping, metal spinning allows for complex geometries in a single operation, reducing assembly time. Heavy industry players, including oil rig builders, favor this technique for its ability to handle metals like aluminum and stainless steel. The result? Durable components that enhance safety and longevity in demanding environments. Spinning technology dates back centuries but has evolved into a cornerstone of modern fabrication processes, particularly for rotationally symmetrical parts in oil spinning applications.

Key Benefits of Metal Spinning in Oil and Gas

Metal spinning boosts efficiency in oil and gas by minimizing material waste and production costs, crucial for large-scale oil rig manufacturing. This method creates seamless cylinders and pipes that eliminate weak points from welding, improving pressure resistance in high-stakes gas industries. Manufacturers achieve faster turnaround times, as spinning forms shapes in one continuous motion, unlike multi-step traditional processes. In oil production, spun metal parts withstand corrosive environments, extending equipment life and cutting maintenance expenses. The process excels in producing lightweight yet robust components from metals suited to oil and gas demands, such as those used in subsea pipelines or rig platforms. Quality control integrates seamlessly, ensuring specifications meet rigorous oil gas industry standards. Overall, metal spinning oil gas applications deliver superior strength-to-weight ratios, vital for transporting heavy machinery to remote sites. Experts note that this technique reduces downtime in gas metal spinning operations, fostering innovation in spinning manufacturing.

Comparison with Traditional Fabrication Processes

Traditional fabrication processes like milling, welding, and stamping often require multiple steps to form oil rig parts, leading to higher costs and potential defects. Metal spinning streamlines this by forming complex shapes from a single metal blank, avoiding seams that compromise integrity in pressure-heavy oil and gas settings. While welding joins pieces but introduces heat-affected zones prone to corrosion, spinning produces monolithic structures ideal for pipes and cylinders in gas production. Stamping limits design flexibility to flat or simple bends, but metal spinning crafts intricate, rotationally symmetrical profiles with minimal tooling changes. In oil rig manufacturing, this translates to lower labor needs and faster cycles—spinning completes a part in minutes versus hours for assembled fabrications. Cost savings shine in high-volume runs for the oil gas industry, where material efficiency trumps wasteful cuttings from milling. Though hand spinning suits prototypes, automated variants outperform traditional methods in precision and scalability for heavy industry demands.

Technological Advances in Metal Spinning

Automation and Robotics in Metal Spinning

Automation revolutionizes metal spinning by integrating robotics to handle heavy metal blanks and precise tool movements, slashing errors in oil rig production. Robotic arms load and unload parts onto spinning machines, enabling 24/7 operations in the oil and gas industry. This technology speeds up fabrication of cylinders and domes for pressure vessels, critical for gas oil spinning tasks. Manufacturers deploy automated systems to maintain consistent force during rotation, ensuring uniform wall thickness in high-pressure components. In spinning industries, robotics reduce human exposure to hazardous environments, boosting safety on oil rigs. Advanced setups incorporate sensors for real-time adjustments, adapting to metal variations like aluminum or stainless steel. The shift from manual hand spinning to automated processes cuts costs by 30-50% in metal fabrication, allowing experts to focus on design innovation. Oil technology benefits immensely, as these systems produce flawless pipes for subsea applications without fatigue-induced flaws.

CNC Technology and Its Impact on Precision

CNC technology elevates metal spinning precision by programming machine tools to follow exact paths, vital for oil rig components that demand tight tolerances. In the oil and gas sector, CNC-controlled lathes spin metal into shapes with micron-level accuracy, far surpassing manual methods. This integration allows for programmable speeds and pressures, optimizing the forming of rotationally symmetrical parts like funnels and housings for gas production equipment. Manufacturers leverage CNC for batch consistency, essential in metal gas applications where deviations could lead to failures under pressure. The technology minimizes scrap in spinning machining oil processes, enhancing efficiency in heavy industry. Experienced operators program complex sequences to handle diverse metals, from aluminum to high-alloy steels, tailoring designs for oil production rigs. CNC's impact extends to reduced setup times, enabling quick shifts between prototypes and full-scale manufacturing. In oil spinning, this precision ensures compliance with specifications, fortifying the backbone of the oil gas industry.

Laser Cutting Integration for Enhanced Efficiency

Laser cutting pairs seamlessly with metal spinning to prepare blanks with unparalleled accuracy, streamlining oil rig manufacturing workflows. High-powered lasers trim metal sheets into precise discs before spinning, eliminating rough edges that could distort final shapes. In oil and gas fabrication, this integration accelerates production of cylinders for pipes and vessels, reducing post-processing needs. Manufacturers use laser technology to etch patterns or score lines, guiding the spinning process for intricate designs in gas industries. The combo cuts material waste and boosts speed—lasers handle thick metals like stainless steel effortlessly, prepping them for automated spinning machines. Efficiency gains shine in spinning oil gas operations, where integrated systems produce seamless components faster than separate fabrication processes. Experts highlight how laser precision enhances wall uniformity in high-pressure environments, crucial for oil rig safety. This advancement also lowers costs by minimizing secondary operations like milling, positioning laser-assisted spinning as a game-changer in metal working.

Material Considerations in Oil Rig Production

Choosing the Right Metals for Oil and Gas Applications

Selecting metals for oil and gas applications hinges on durability, corrosion resistance, and formability during metal spinning, directly impacting rig efficiency. Carbon steels offer cost-effective strength for structural cylinders, while alloys excel in corrosive offshore settings. Manufacturers evaluate factors like yield strength and ductility to ensure metals withstand extreme pressures in gas production. In oil rig design, choosing metals that spin well—such as low-carbon variants—prevents cracking during rotation. The oil gas industry prioritizes materials compatible with lubricants and chemicals, avoiding degradation in harsh environments. Experts recommend testing samples in simulated conditions to match specifications for pipes and housings. Aluminum emerges for lightweight needs in transportable rig sections, balancing cost with performance. Proper selection drives innovation in metal fabrication, ensuring long-term reliability in spinning manufacturing for oil technology.

The Role of Stainless Steel and Aluminum in Design

Stainless steel anchors oil rig designs with its unmatched corrosion resistance, ideal for spun cylinders exposed to saltwater and chemicals in the oil and gas industry. During metal spinning, this metal forms seamless shapes that resist pitting, extending service life in gas oil spinning applications. Aluminum complements it by providing lightweight alternatives for non-structural parts, easing installation on remote rigs. Designers spin aluminum into thin-walled pipes that maintain pressure integrity without excess weight, cutting shipping costs. In fabrication processes, stainless steel's work-hardening properties demand skilled control, but yield robust housings for valves and pumps. Aluminum's high ductility suits rapid prototyping in hand spinning, accelerating development in oil production. Together, these metals enable versatile designs, from subsea components to platform superstructures. Manufacturers blend them strategically, optimizing for cost, strength, and environmental demands in metal working.

Advanced Materials for High-Pressure Environments

Advanced materials like titanium alloys and nickel-based superalloys fortify high-pressure environments in oil rigs, thriving under metal spinning to create resilient components. These metals endure extreme temperatures and pressures in deepwater gas production, forming impermeable cylinders without welds. In the oil gas industry, their superior fatigue resistance prevents failures in pulsating flow lines. Spinning these materials requires specialized machines to manage their hardness, but the payoff is seamless shapes for chemical industry crossovers. Manufacturers incorporate composites with metals for hybrid parts, enhancing lightness while preserving strength. Advanced materials address challenges in oil lubricant compatibility, reducing wear in spinning machining oil setups. Experts push boundaries with nanomaterials to boost corrosion barriers, innovating for future oil technology. This focus ensures oil rig parts perform reliably, driving efficiency in heavy industry fabrication.

Quality Control and Specifications in Metal Forming

Tolerances and Quality Assurance in Manufacturing

Tolerances define success in metal forming for oil rigs, where even minor deviations can jeopardize pressure vessel integrity in oil and gas operations. Manufacturers set strict limits—often ±0.005 inches—for spun cylinders to ensure fit in assemblies. Quality assurance involves ultrasonic testing and dimensional checks post-spinning, verifying wall thickness uniformity. In gas industries, these measures catch flaws from metal variations, preventing costly recalls. Automated gauges monitor during production, integrating with CNC systems for real-time corrections. Experienced teams calibrate machines to meet specifications, balancing precision with speed in fabrication processes. This rigor applies to diverse metals, from aluminum to stainless steel, ensuring rotationally symmetrical parts align perfectly. Ultimately, robust tolerances and assurance protocols elevate reliability, safeguarding lives and investments in the oil gas industry.

Implementing Quality Control Systems in Metal Fabrication

Implementing quality control systems in metal fabrication starts with standardized protocols that track every stage from blank preparation to final spinning in oil rig production. Integrated software logs data on machine tools and material properties, flagging anomalies in real-time for the oil and gas sector. Manufacturers train staff on ISO-compliant inspections, focusing on weld-free seams critical for pressure resistance. In spinning manufacturing, vision systems scan for surface defects, ensuring pipes meet gas production standards. These systems reduce variability in automated runs, enhancing consistency across batches. For heavy industry, traceability links parts to raw metals, aiding audits in chemical industry parallels. Experts emphasize preventive maintenance on spinning machines to sustain quality, minimizing downtime. Such implementations not only comply with regulations but also drive cost efficiencies through fewer rejects in metal working.

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards like API and ASME fortifies metal forming outputs for oil rigs, mandating rigorous testing in oil and gas fabrication. Manufacturers certify processes through third-party audits, verifying that spun components endure simulated pressures and corrosives. Specifications dictate material certifications and spinning parameters, aligning with global oil gas industry norms. In gas metal spinning, non-destructive evaluations confirm internal integrity without compromising shapes. Compliance extends to environmental regs, tracking emissions from laser cutting integrations. Experts document every step, from design to delivery, for traceability in high-stakes applications. This adherence builds trust with operators, enabling seamless integration into rigs for oil production. Ultimately, standards compliance turns metal fabrication into a reliable pillar of innovation and safety in spinning industries.

Future Trends and Innovations in Metal Spinning

Emerging Technologies in the Oil and Gas Industry

Emerging technologies like AI-driven predictive modeling transform metal spinning in the oil and gas industry, forecasting optimal parameters for complex shapes. Additive manufacturing hybrids with spinning create reinforced cylinders for ultra-high-pressure gas production, blending layers before forming. In oil rig evolution, 3D scanning refines designs, ensuring precision in automated fabrication. Manufacturers explore hybrid machines combining spinning with milling for intricate oil technology parts. These innovations address spinning gas challenges, like variable viscosities in lubricants affecting metal flow. Robotics with machine learning adapt mid-process, enhancing efficiency in heavy industry. Experts predict quantum sensors for nanoscale quality control, revolutionizing tolerances. As oil gas demands grow, these technologies promise faster, greener production of pipes and vessels.

The Impact of Sustainability on Metal Fabrication

Sustainability reshapes metal fabrication by prioritizing recyclable metals and energy-efficient spinning processes in oil rig manufacturing. Manufacturers adopt low-emission CNC machines, cutting power use in aluminum and stainless steel forming for the oil and gas sector. Recycling programs reclaim scrap from laser cutting, reducing waste in gas industries. Green innovations include water-based lubricants over oils, minimizing environmental impact in spinning manufacturing. In oil production, sustainable practices extend to sourcing conflict-free metals, aligning with global standards. Experts integrate solar-powered automation, lowering carbon footprints for offshore rigs. This shift not only complies with regs but boosts cost savings through efficient resource use. Sustainability drives innovation, making metal working a leader in eco-friendly heavy industry solutions.

Exploring New Applications in Aerospace and Automotive Industries

New applications in aerospace and automotive industries expand metal spinning's reach, adapting oil and gas techniques for lightweight, high-strength parts. Aerospace firms spin titanium cones for engine housings, mirroring pressure vessel designs from oil rigs. In the automotive industry, aluminum cylinders form exhaust systems, leveraging seamless fabrication for emission controls. Manufacturers cross-pollinate technologies, like CNC precision from gas metal spinning into aircraft fuselages. These sectors benefit from spinning's cost efficiencies, producing rotationally symmetrical components faster than traditional methods. Innovations in advanced materials trickle down, enhancing durability in automotive oil lubricant systems. Experts see hybrid uses in electric vehicles, where spun metal casings house batteries akin to oil tech enclosures. This exploration fosters broader adoption, linking heavy industry with agile manufacturing realms.

See Also

- How Robotics is Shaping the Future of Metal Fabrication in Oil and Gas

- The Future of Automated Metal Spinning in Heavy Industry Applications

- Metal Spinning Innovations Driving Sustainability in Energy Production

- Understanding Tolerances in Metal Spinning for Precision Oil Equipment

- Innovative Metal Spinning Techniques Transforming the Oil and Gas Sector